COMPANY OFFERS

We do everything we can to keep your production running perfectly. With our experience, hundreds of repairs and with our suppliers, we will restore your production to full capacity.

OUR TEAM OF SERVICE TECHNICIANS and ENGINEERS are specialised in most brands of machines:

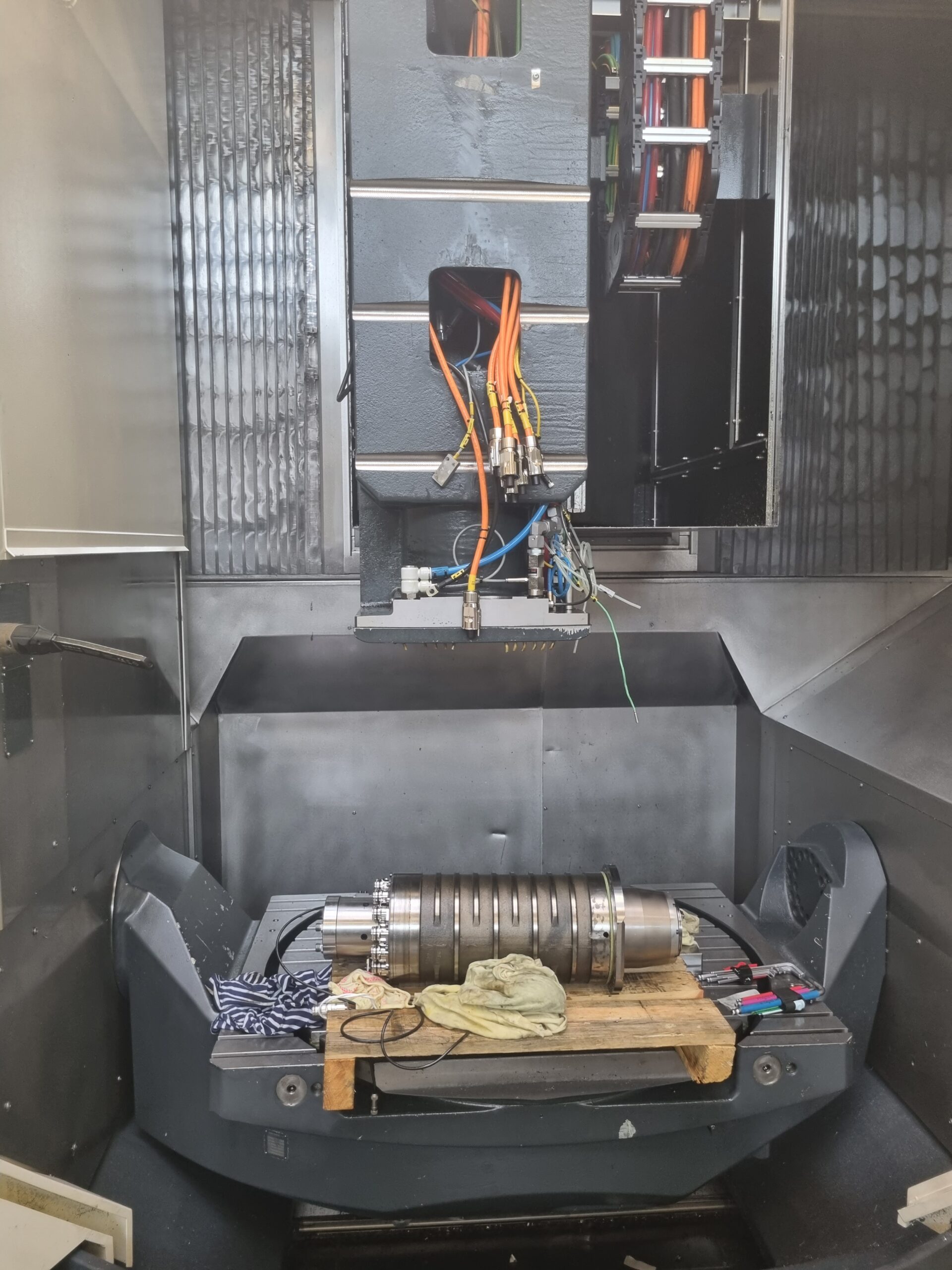

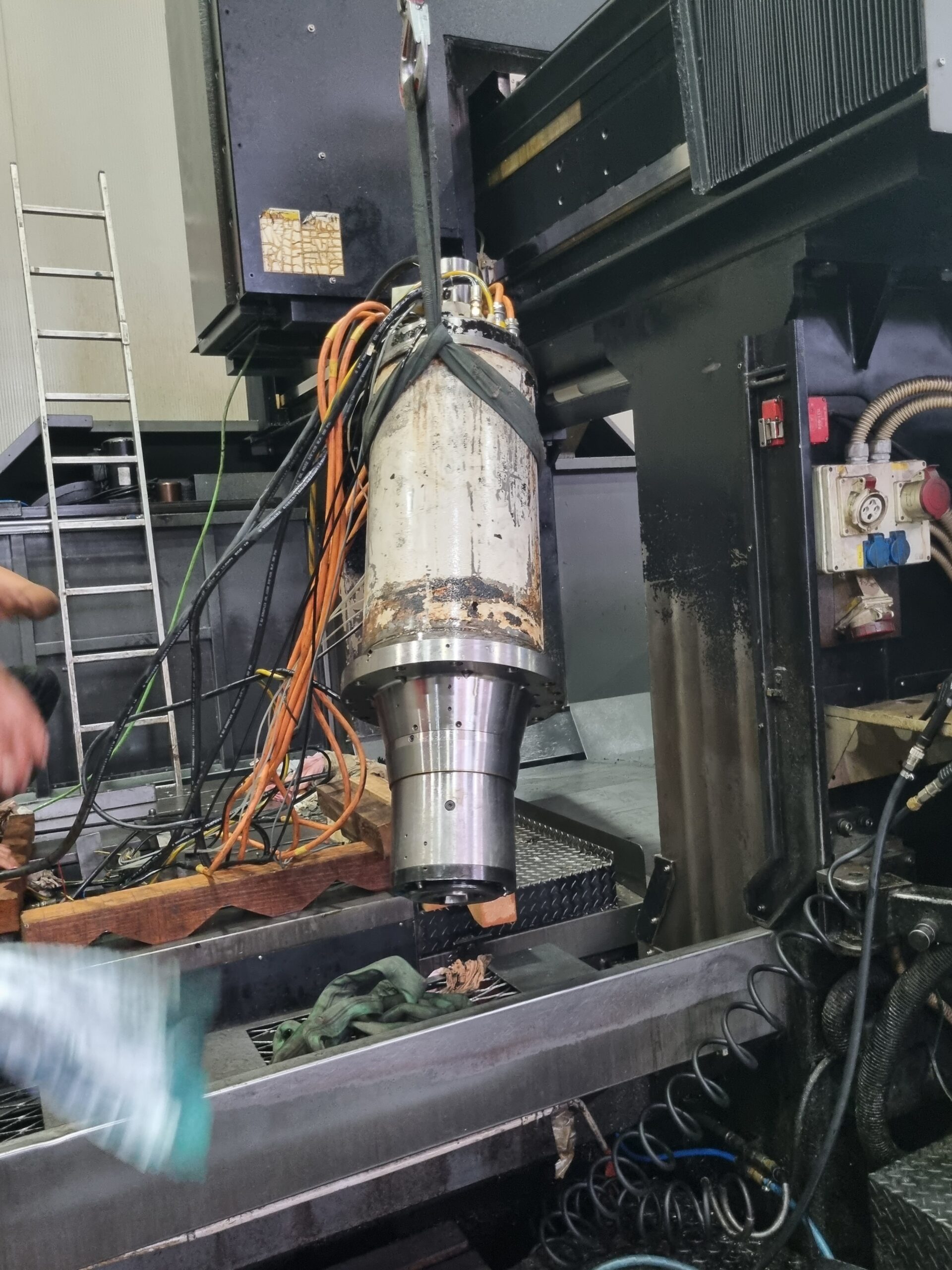

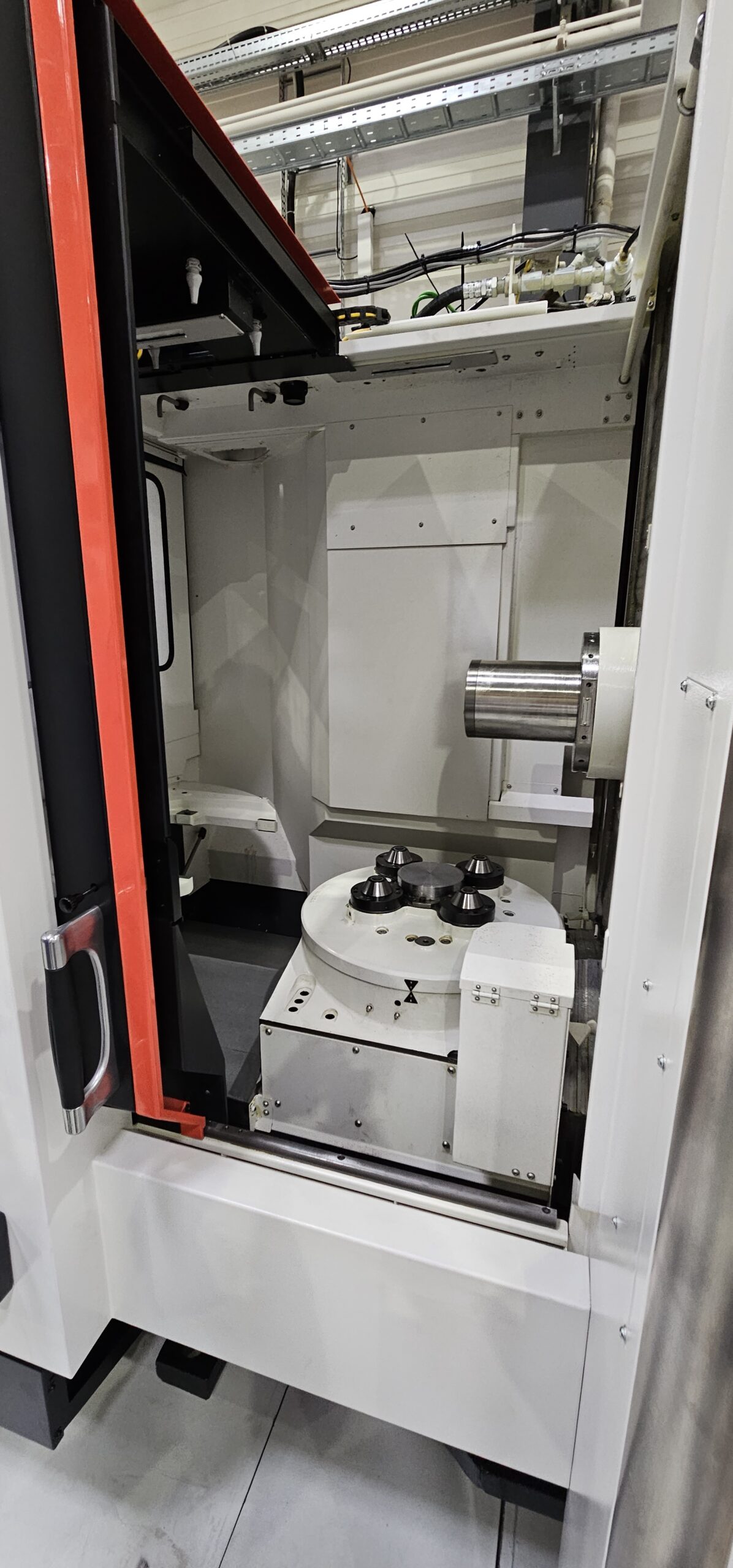

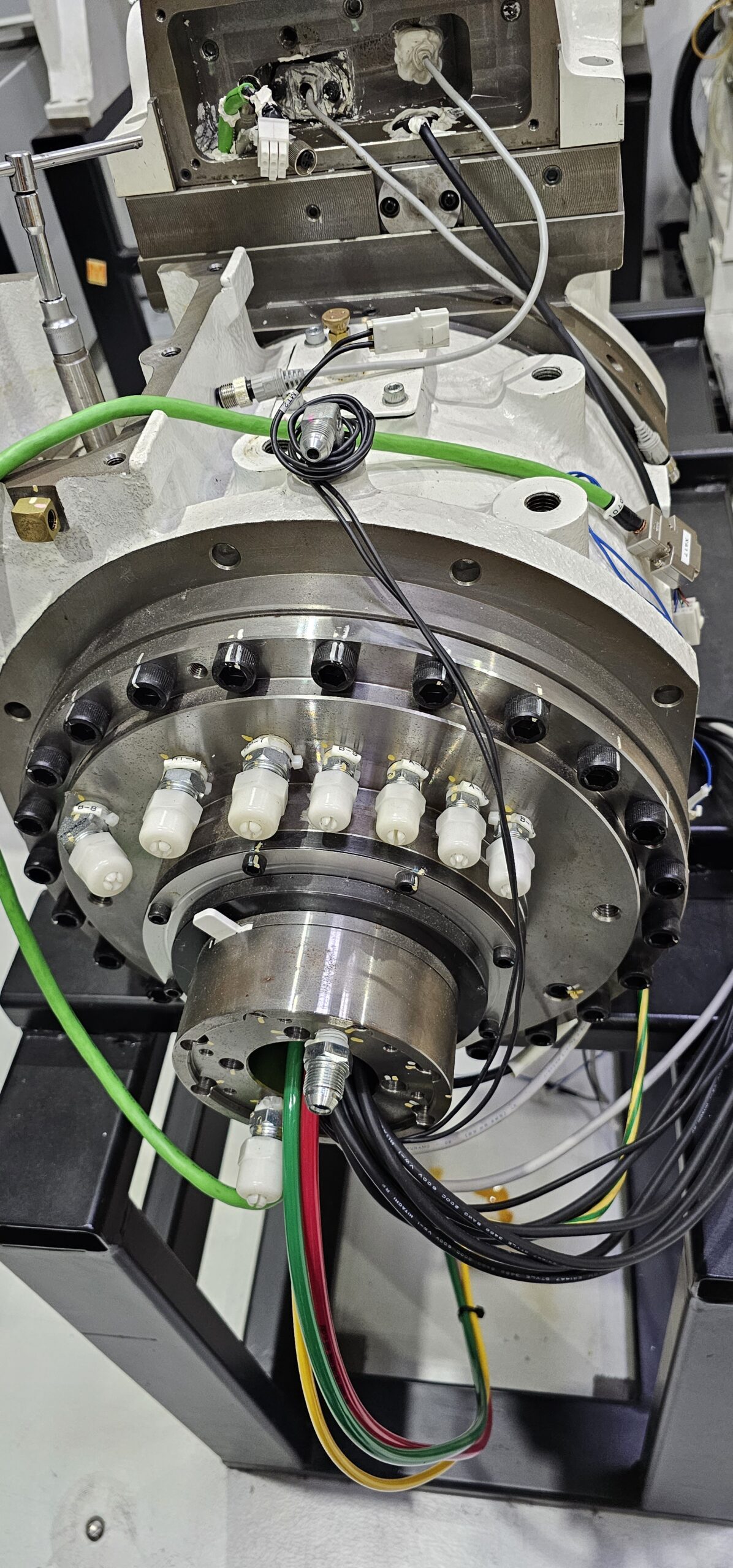

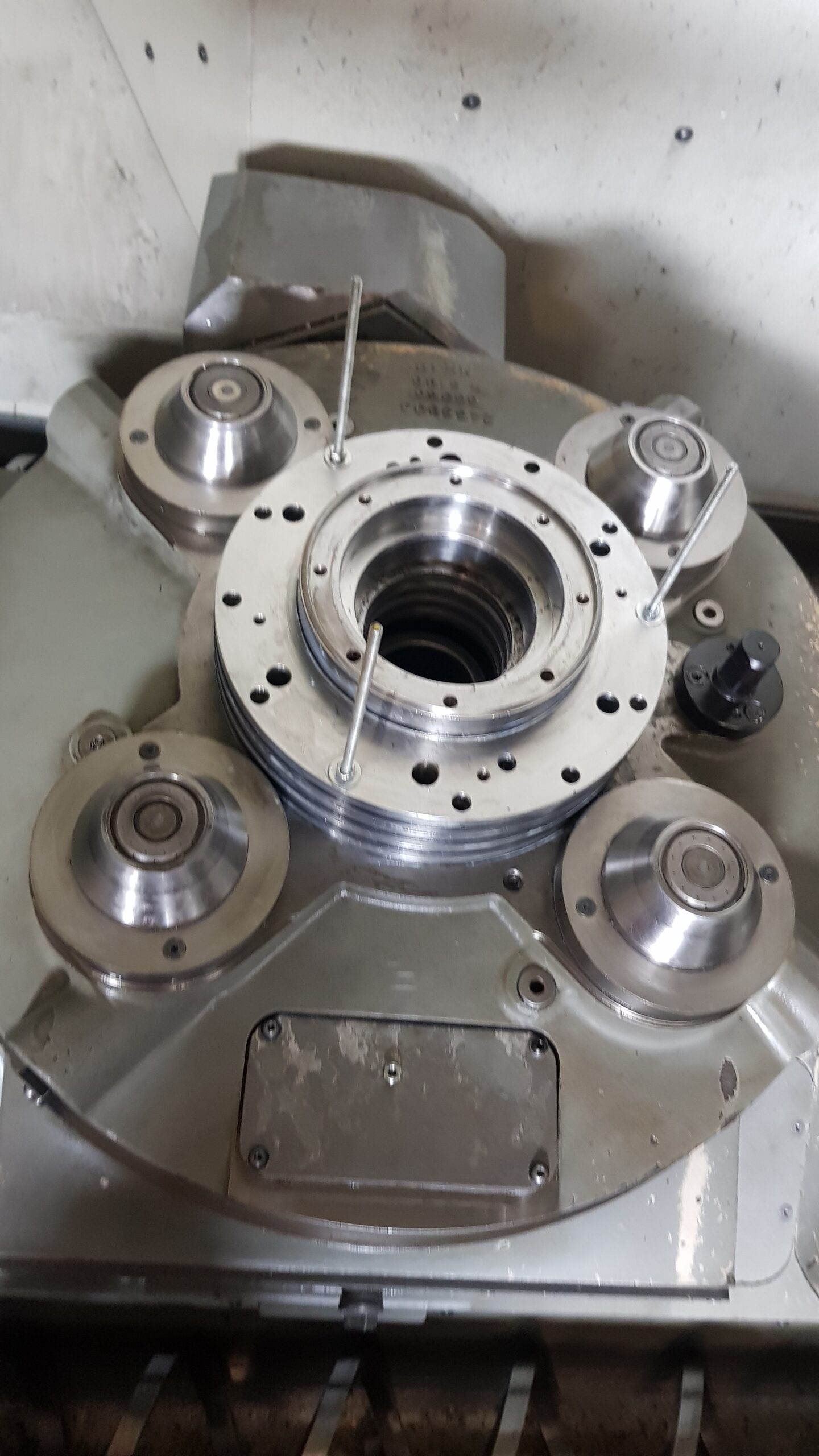

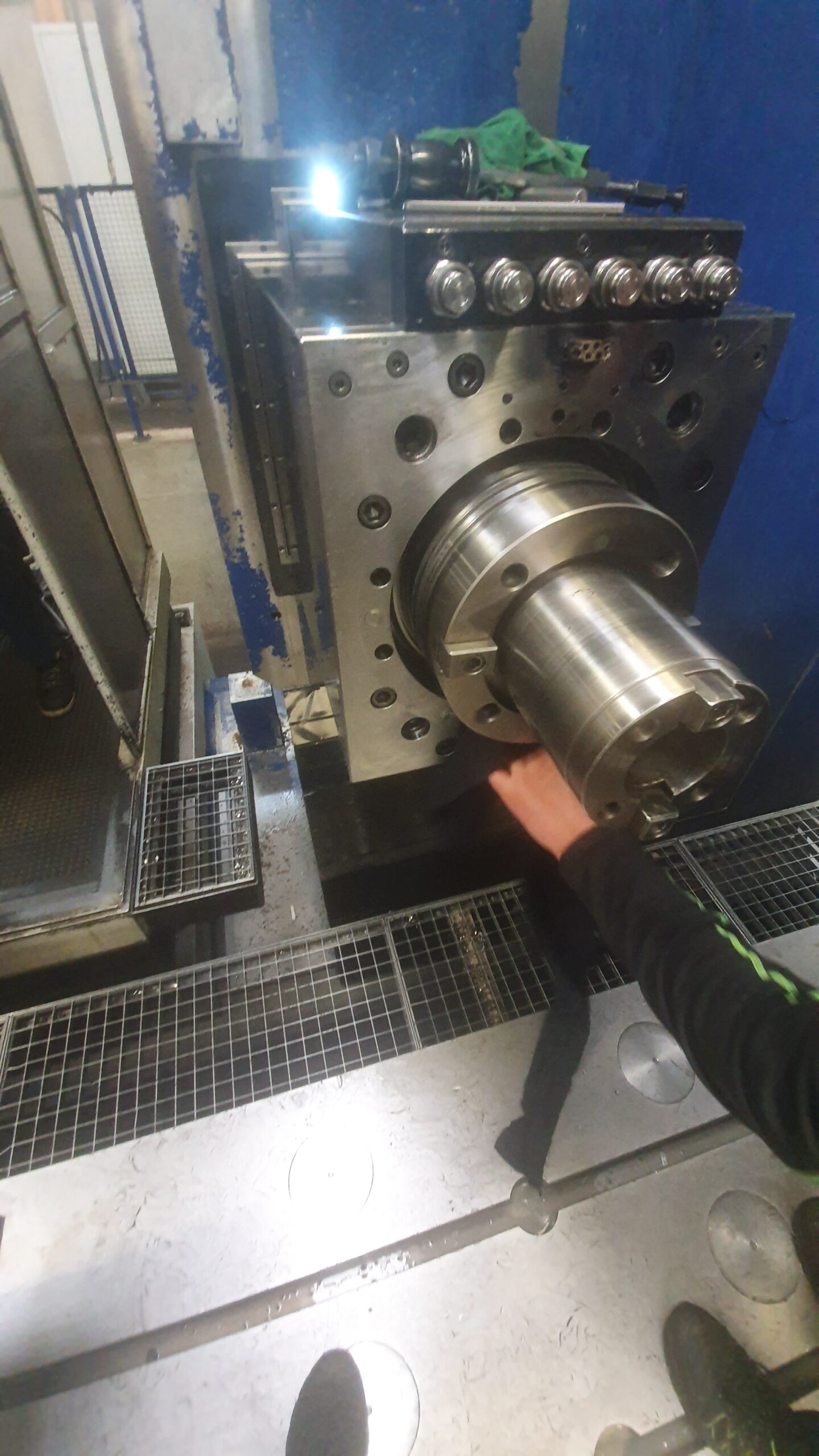

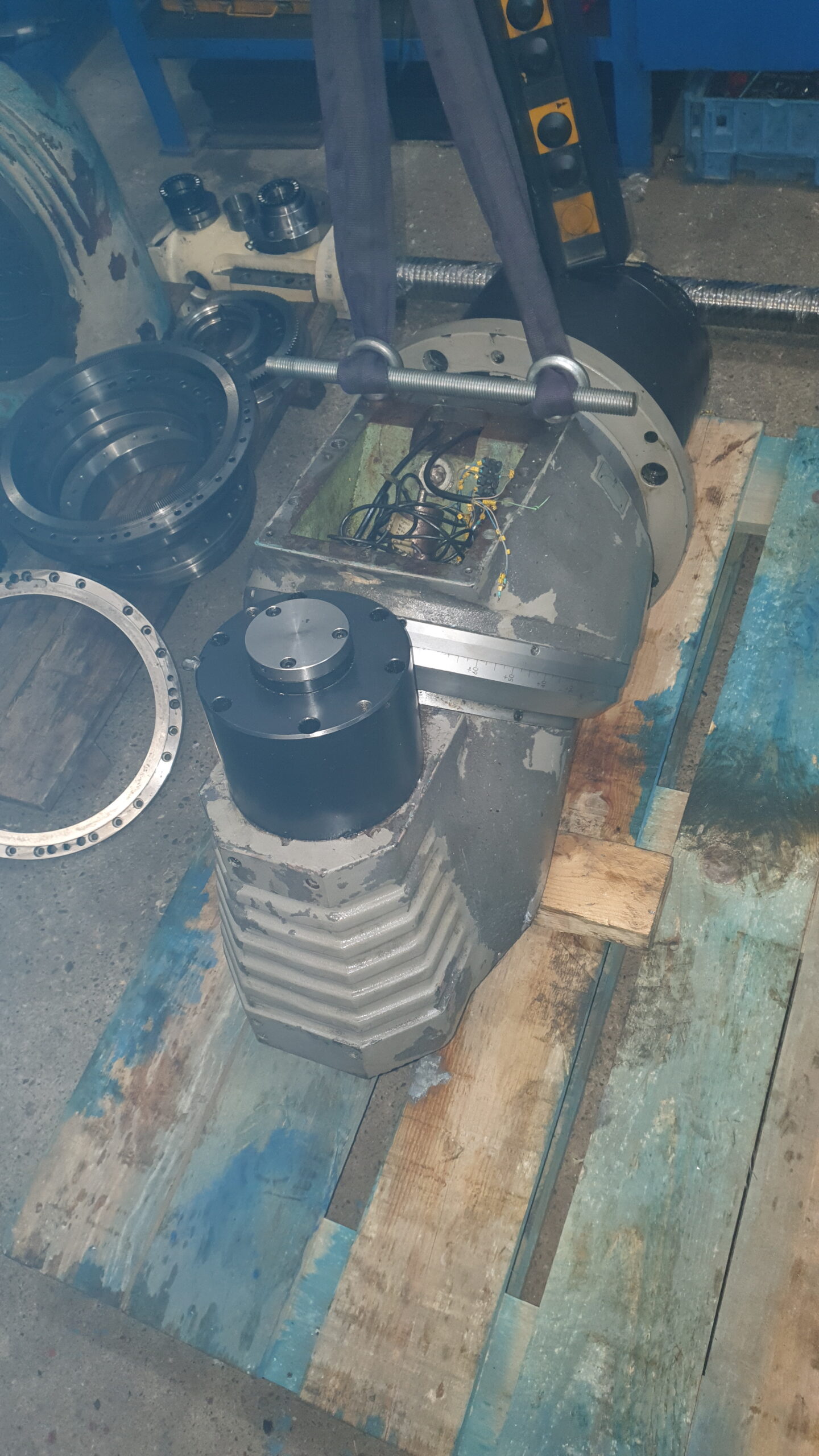

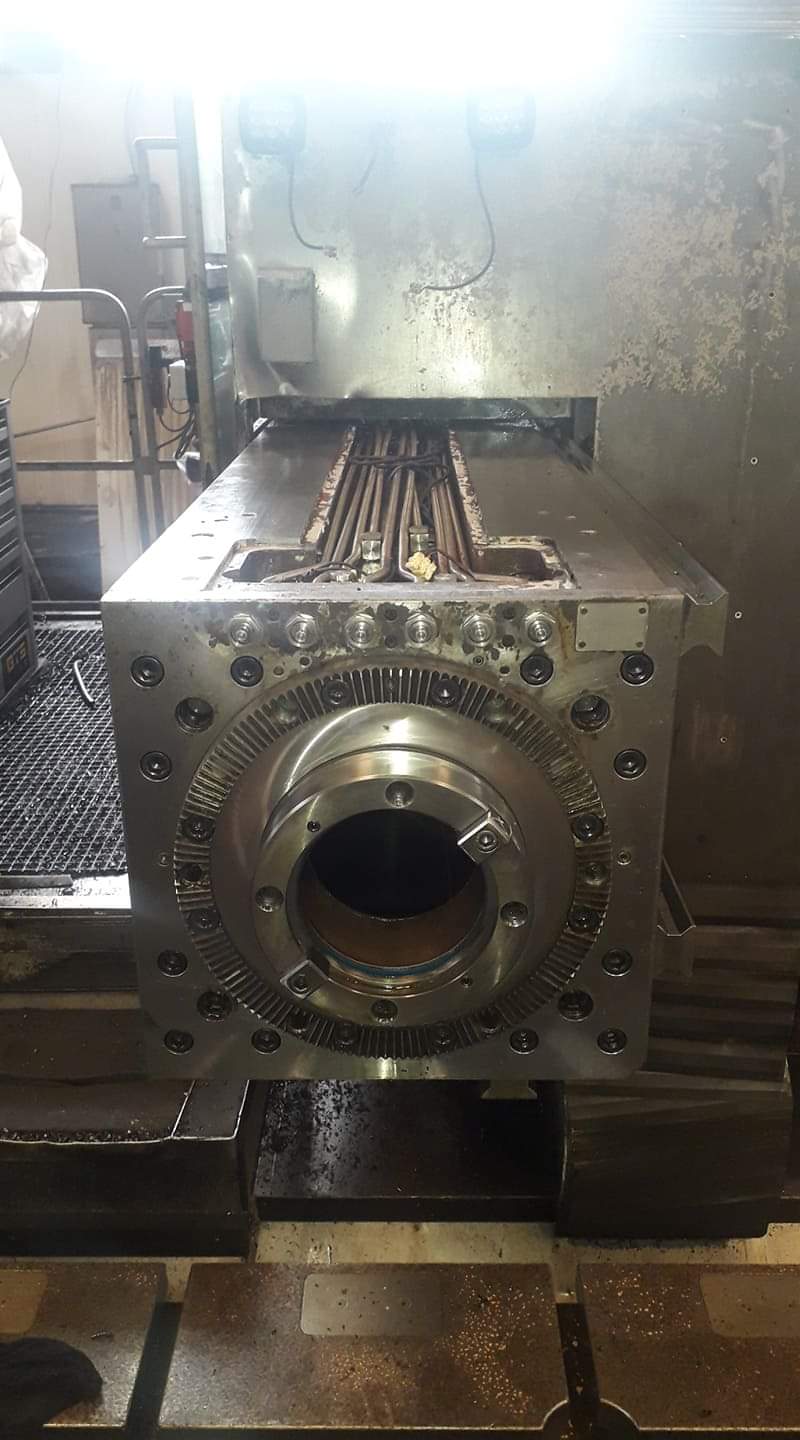

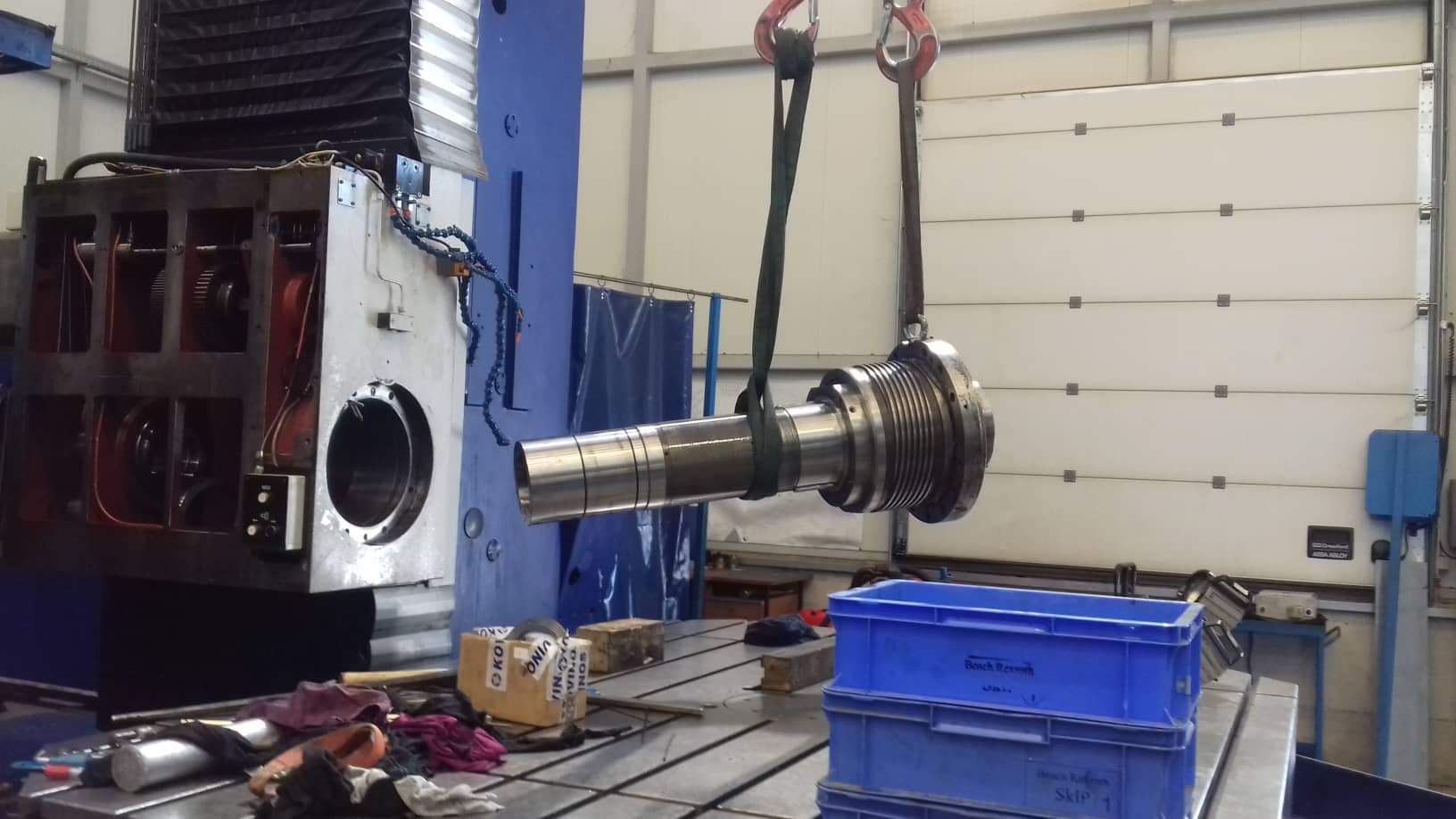

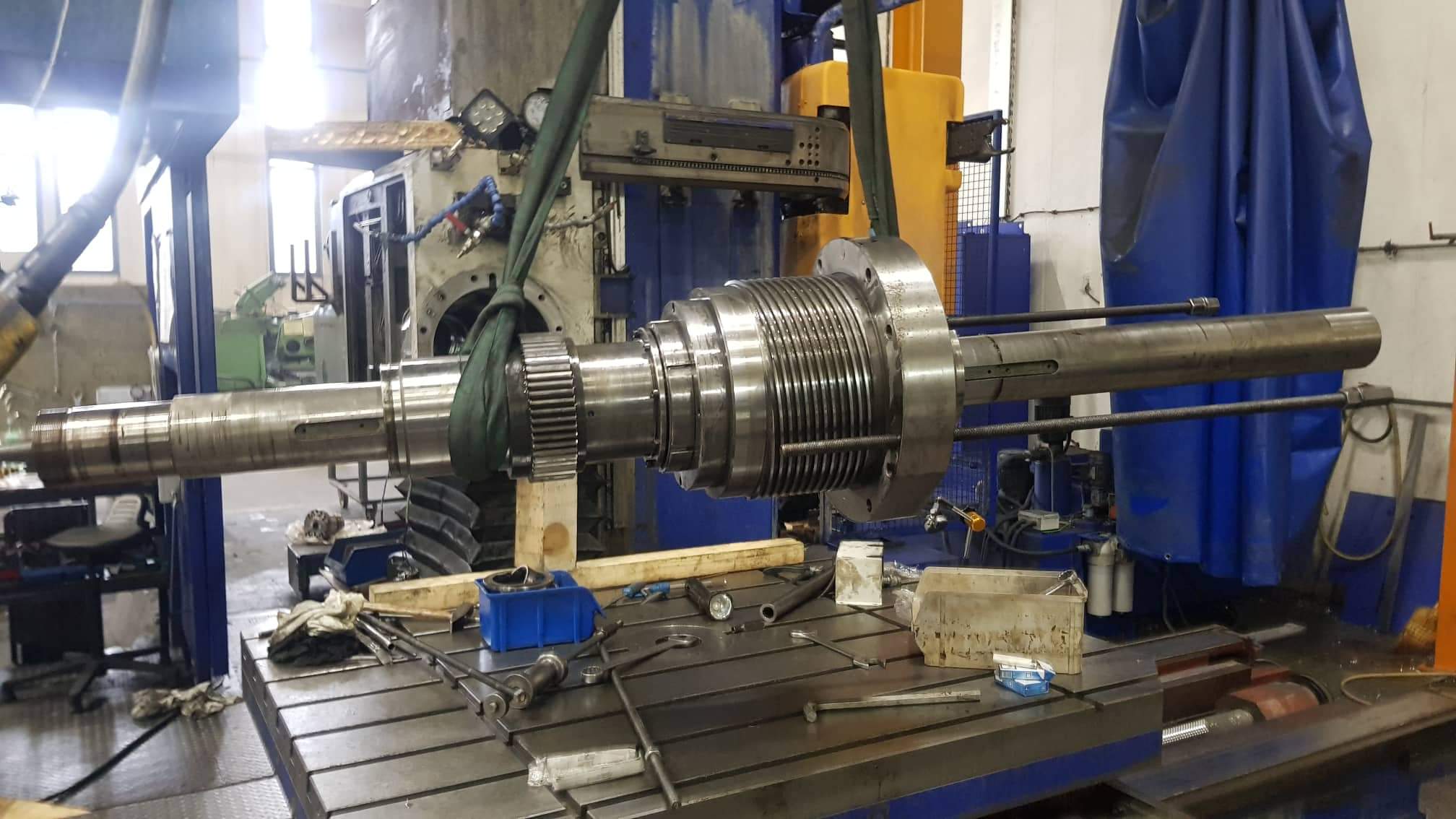

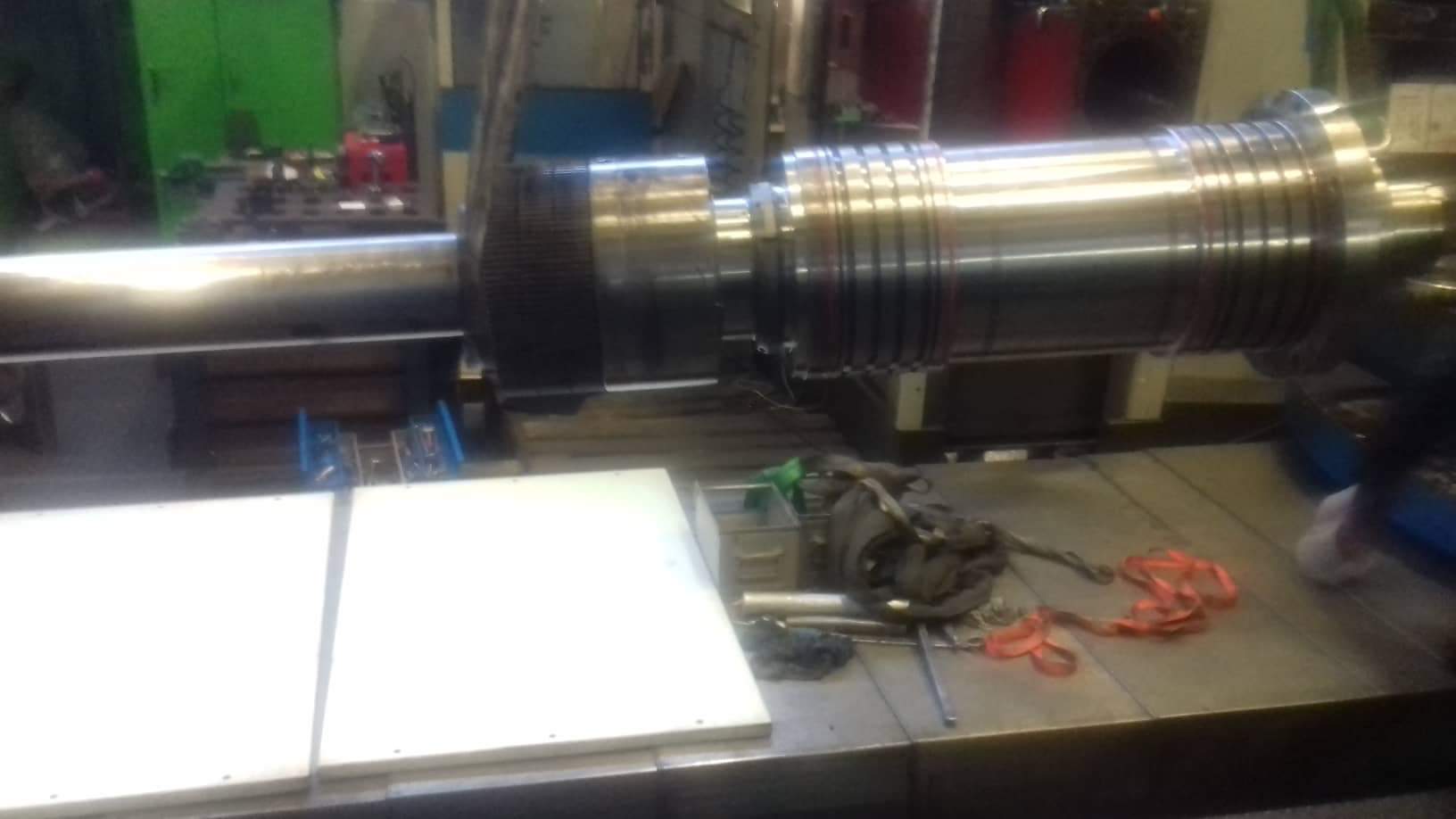

SPINDL SERVICE

Whether it’s a simple bearing repair or a replacement, an overhaul of the clamping system or a complete repair of your spindle – we will provide you with your individual offer.

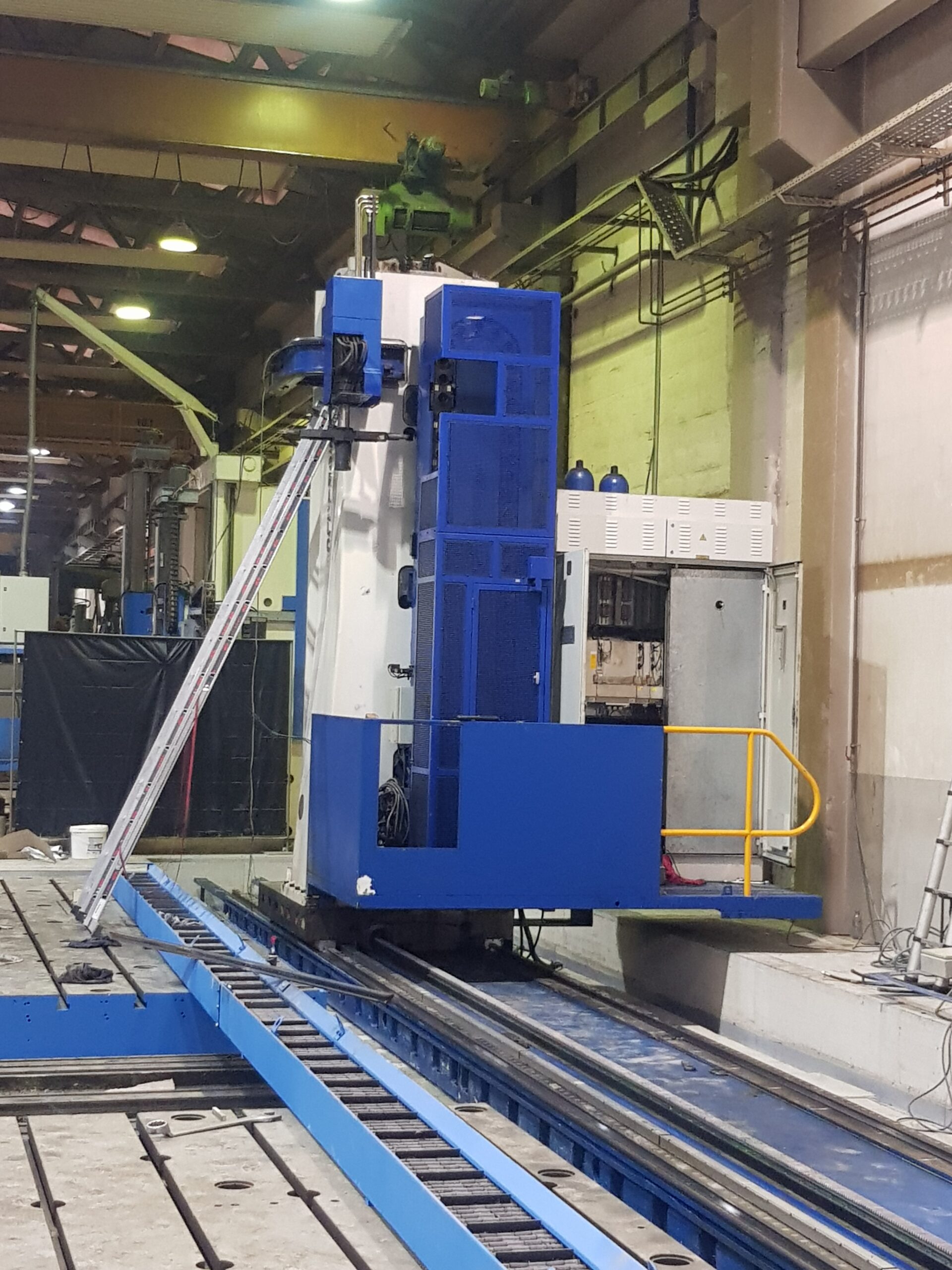

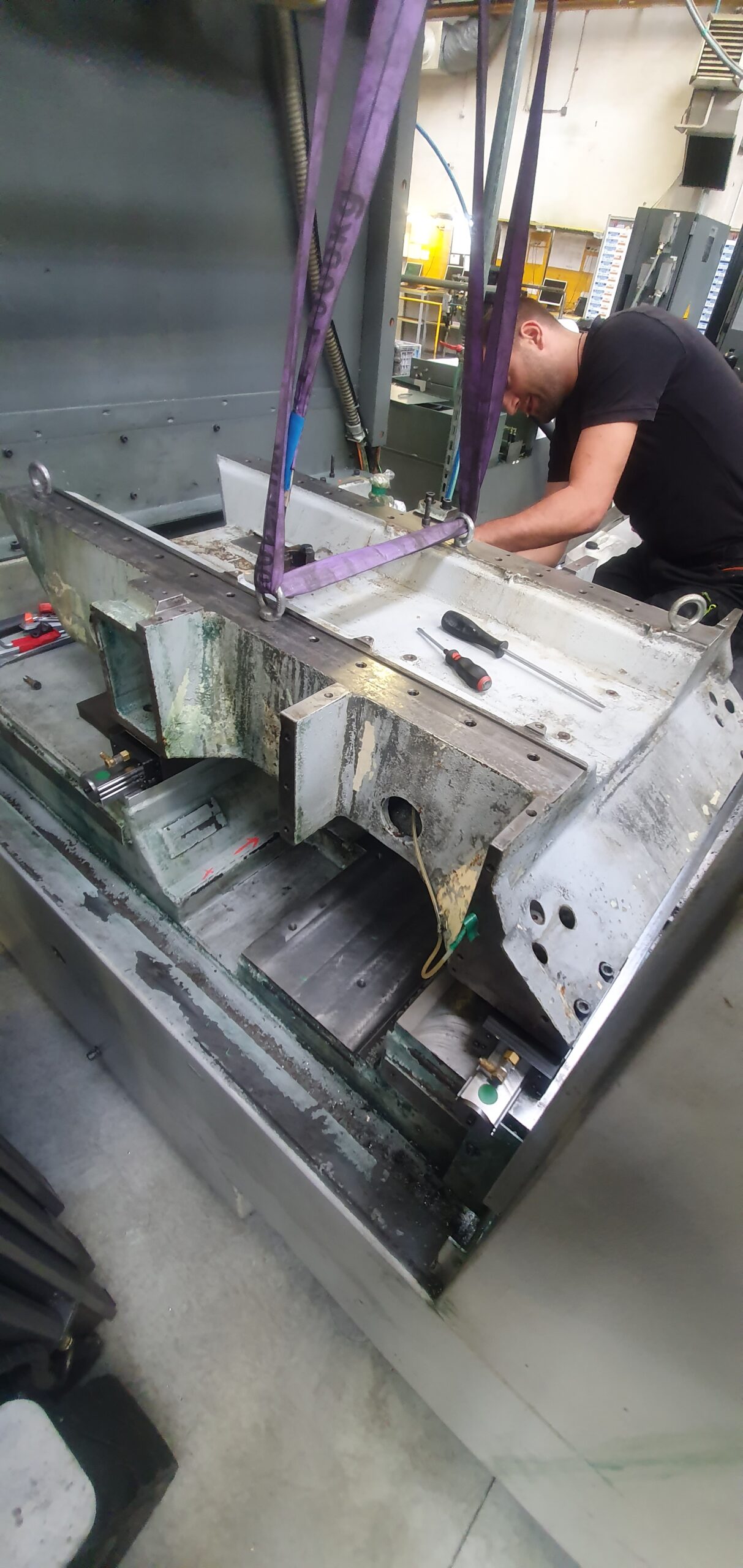

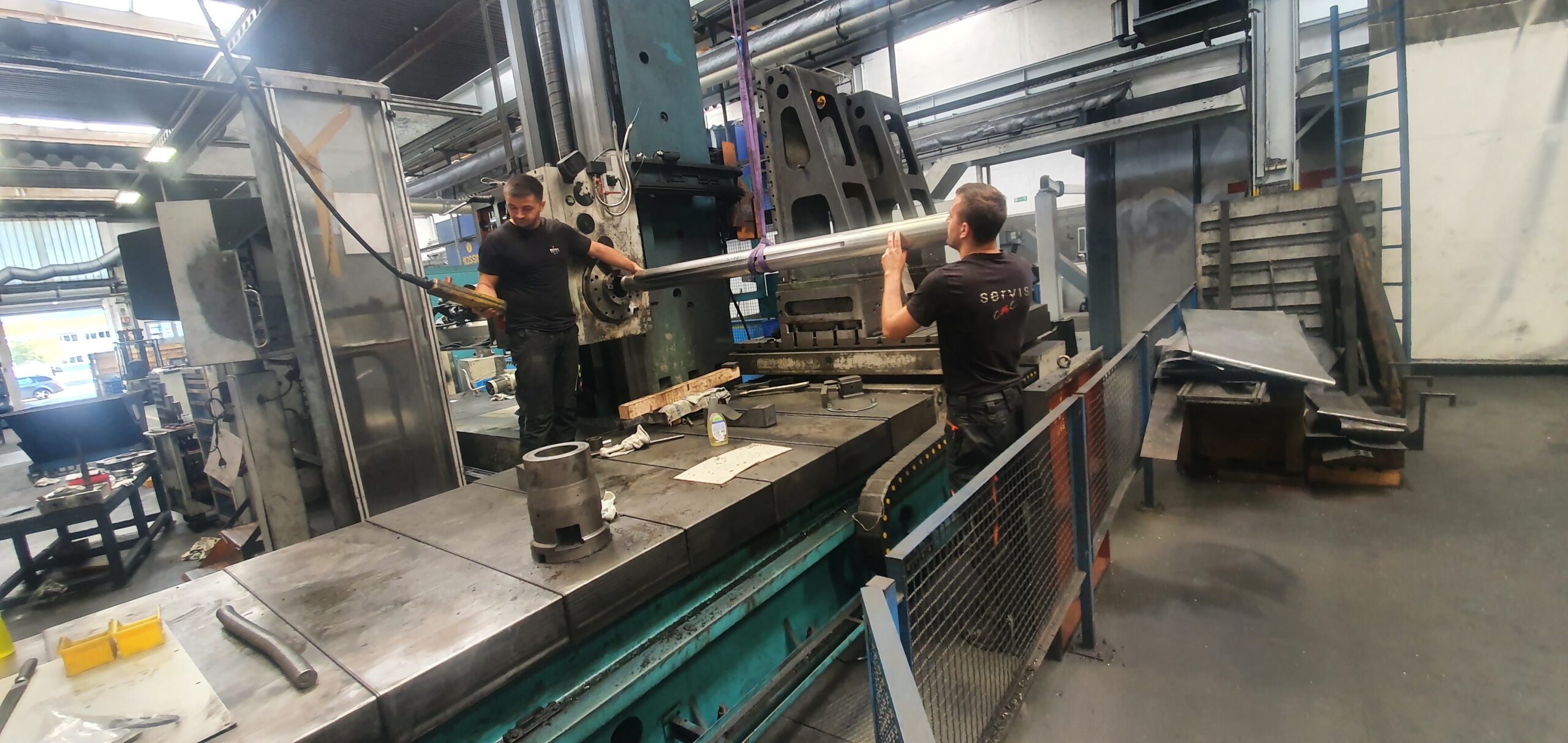

MACHINE SERVICE

In addition to spare parts procurement, comprehensive services or long-term maintenance contracts, we support your company with tailor-made solutions. In case of machine breakdowns, we support you PROFESSIONALLY,, RELIABLY AND QUICKLY..

Our service technicians at STZS CNC d.o.o. are specialised in machines from a wide range of manufacturers. Fast action with the highest possible quality is everyone’s goal, so that your machine can start production again.

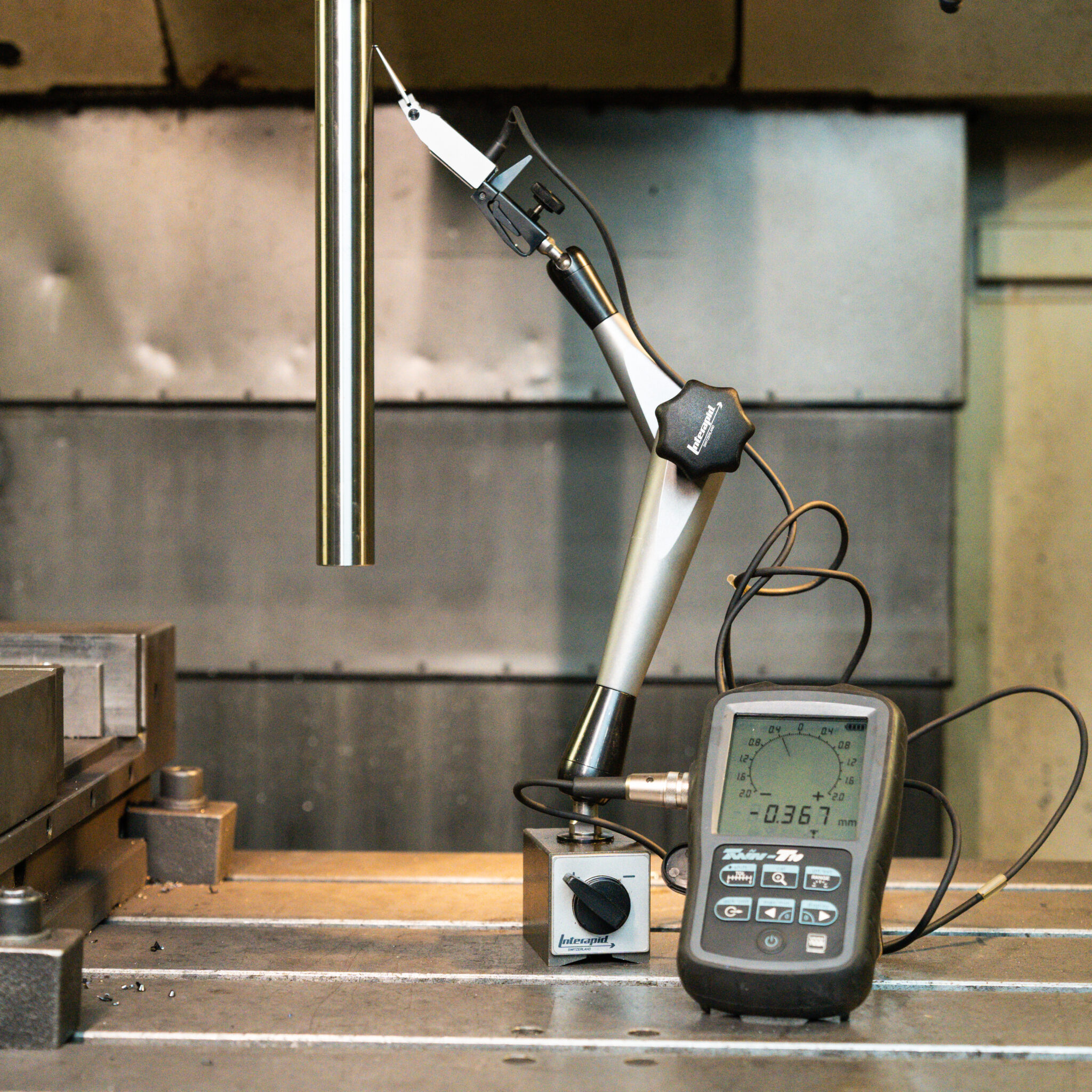

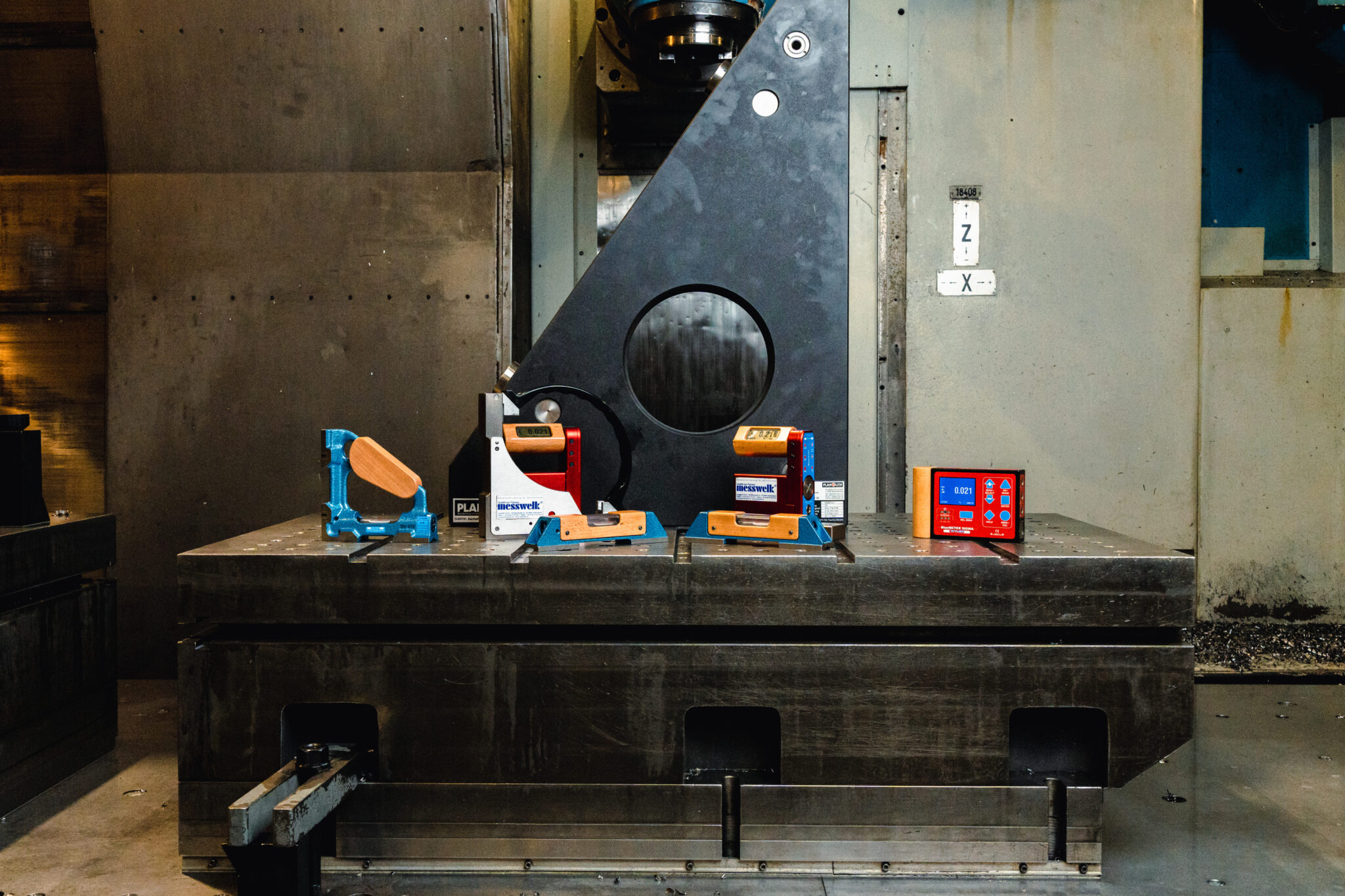

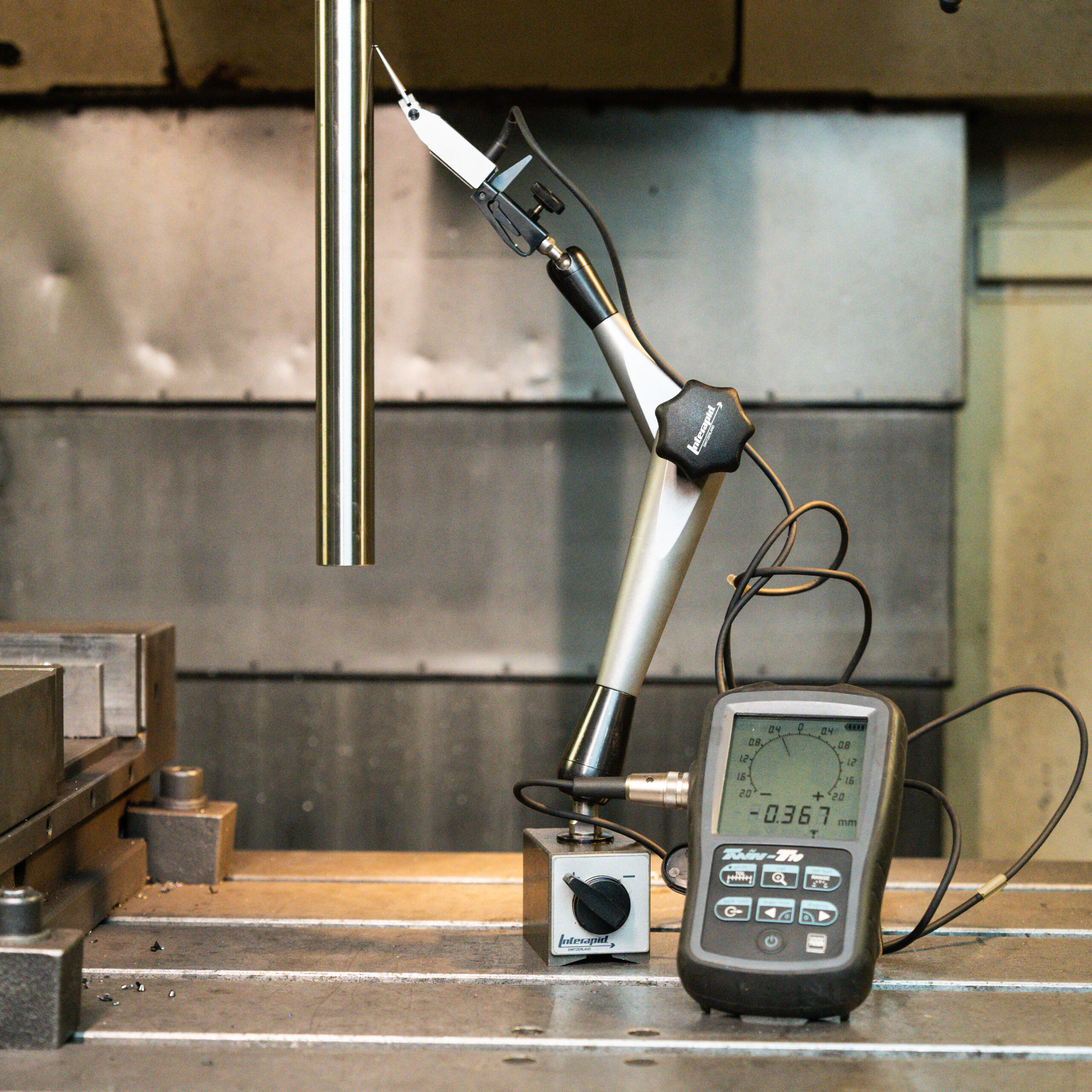

MACHINE GEOMETRY

Regular maintenance and adjustment of the machine geometry of your machine tools helps to prevent machine downtime and ensure precision components. We maintain your machines individually and according to your requirements. After analysing the maintenance needs of your milling and turning machines, we create a maintenance and set-up package tailored to your needs. After an inspection of your machine, we will be happy to offer you an individual and free quotation.

GRINDING OF GUIDES AND REPLACEMENT OF TEFLON

We grind all types of guideways up to a length of 8000 mm. We grind them with high precision accuracy, but since grinding alone is not enough when renewing guides, we are specialised in changing several types of anti-guides (Teflon).

We change and manually process (scrape) PTFE TEFLONE and MOGHLICE-DIAMOND TEFLONE, which are cast in a special way on a pre-prepared surface. We have several types of these in stock, so we can replace them quickly.

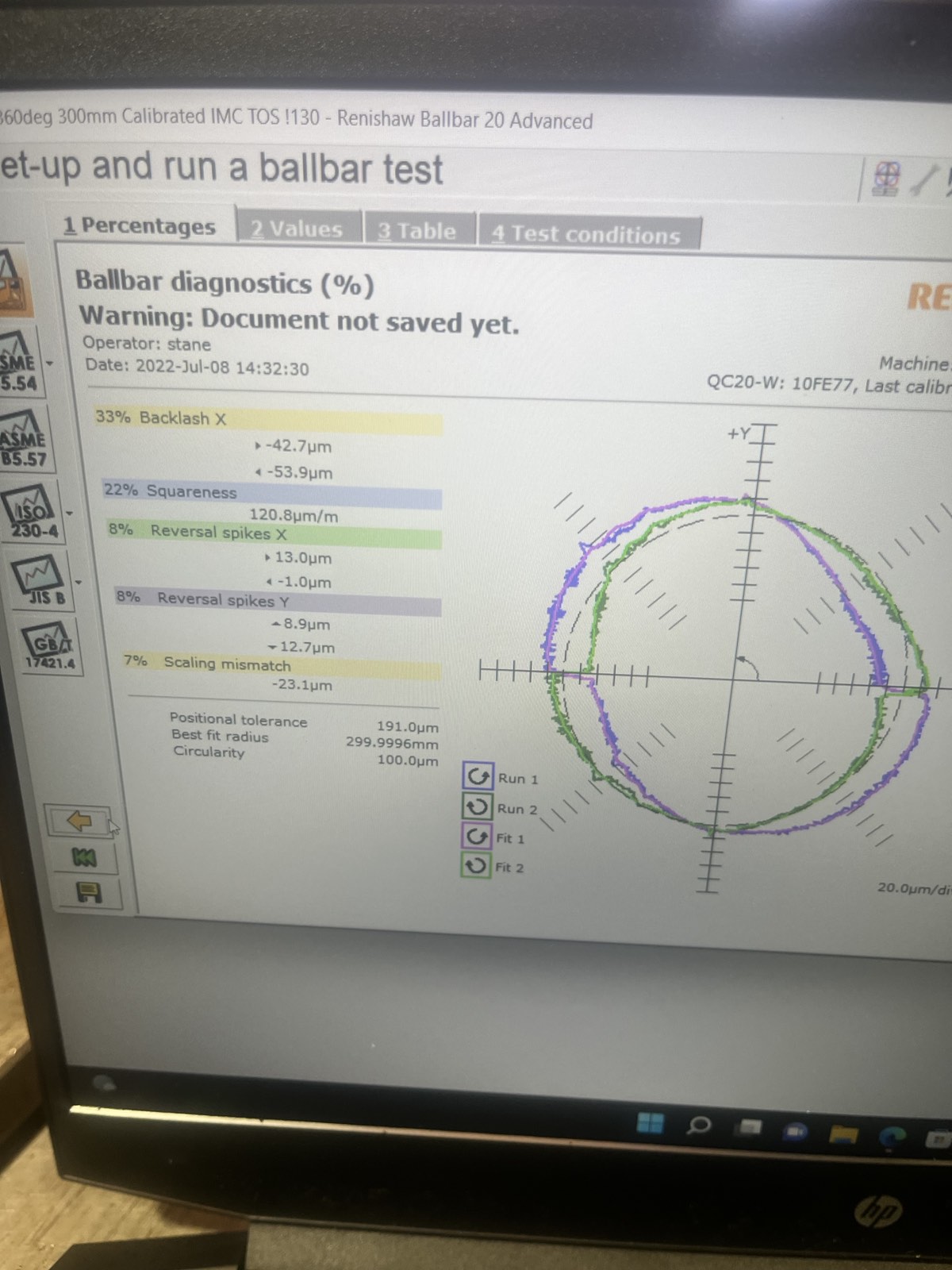

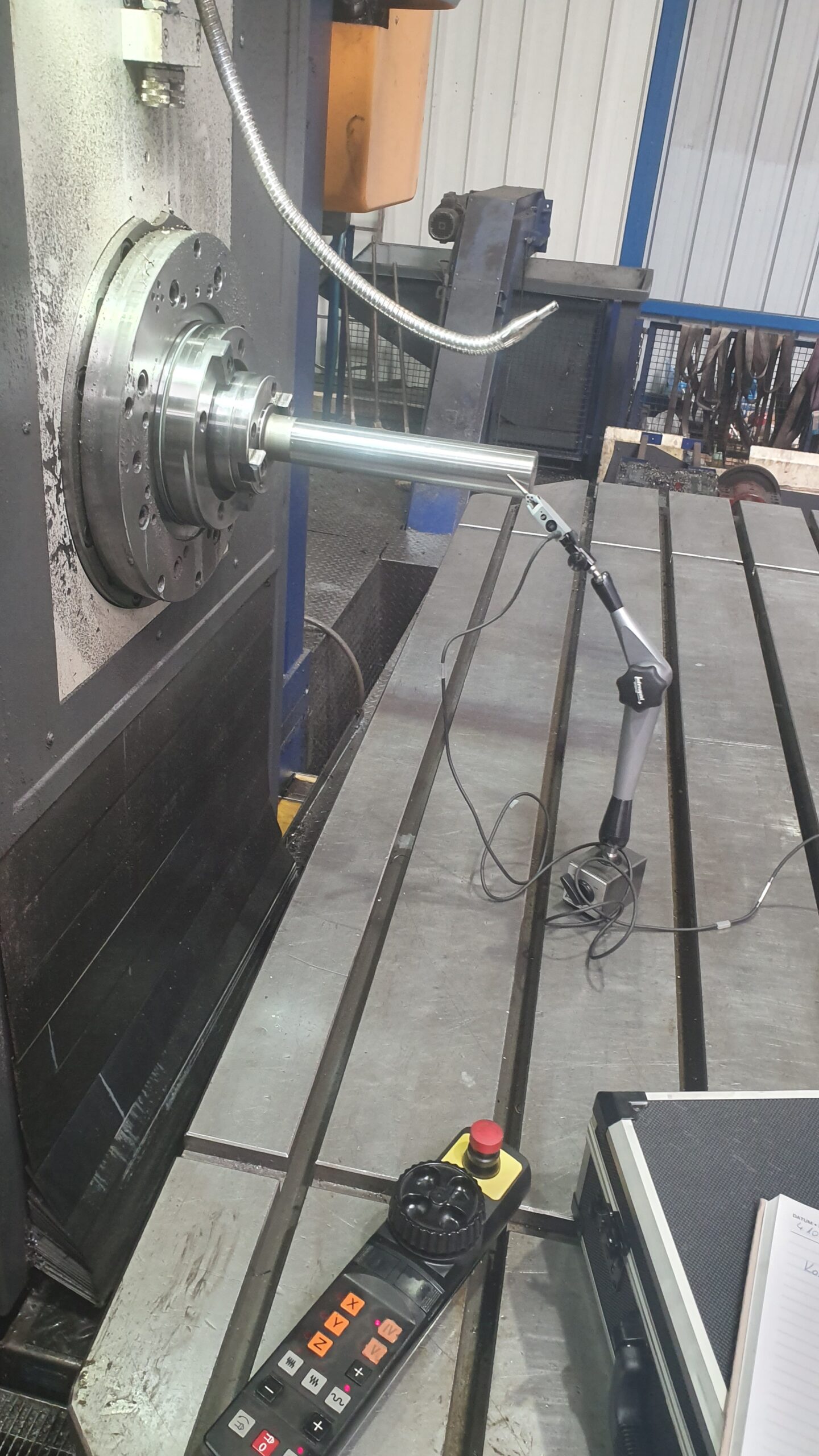

RENISHAW – BALLBAR MEASUREMENTS AND SETTINGS

Testing with the QC20 provides a simple and quick check of a CNC machine tool’s positioning capabilities against recognised international ISO standards. We make and set all parameter corrections on the machines.

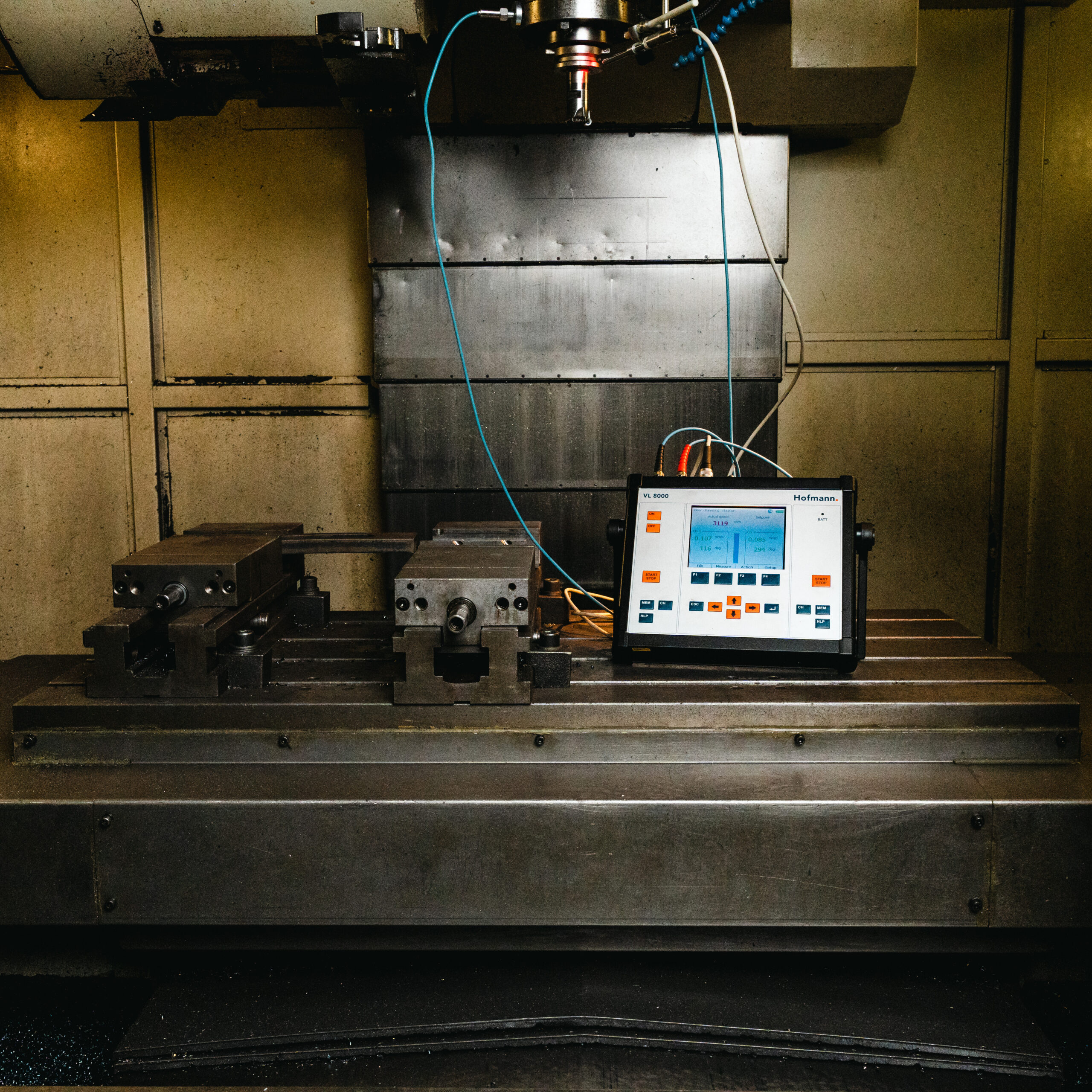

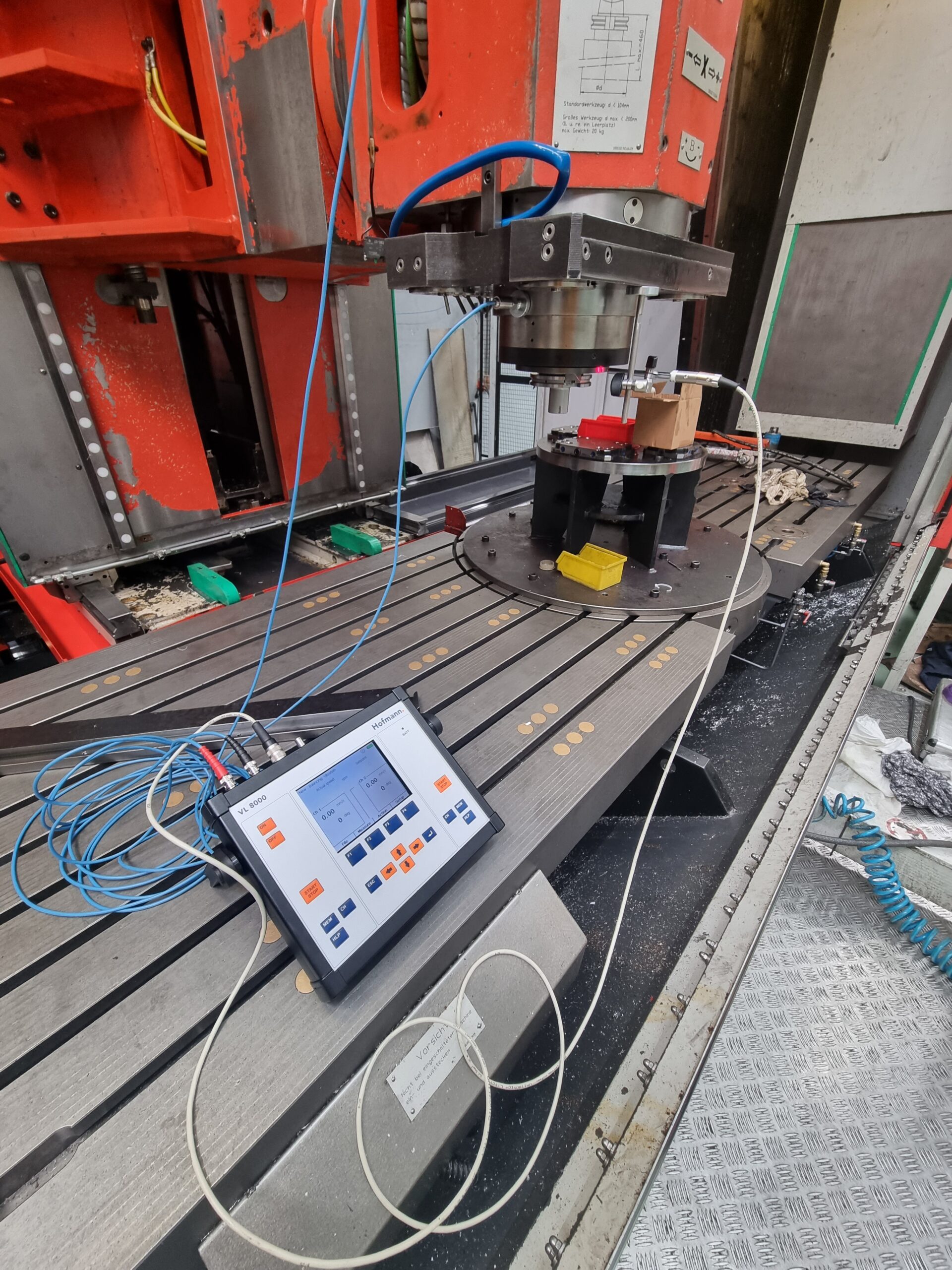

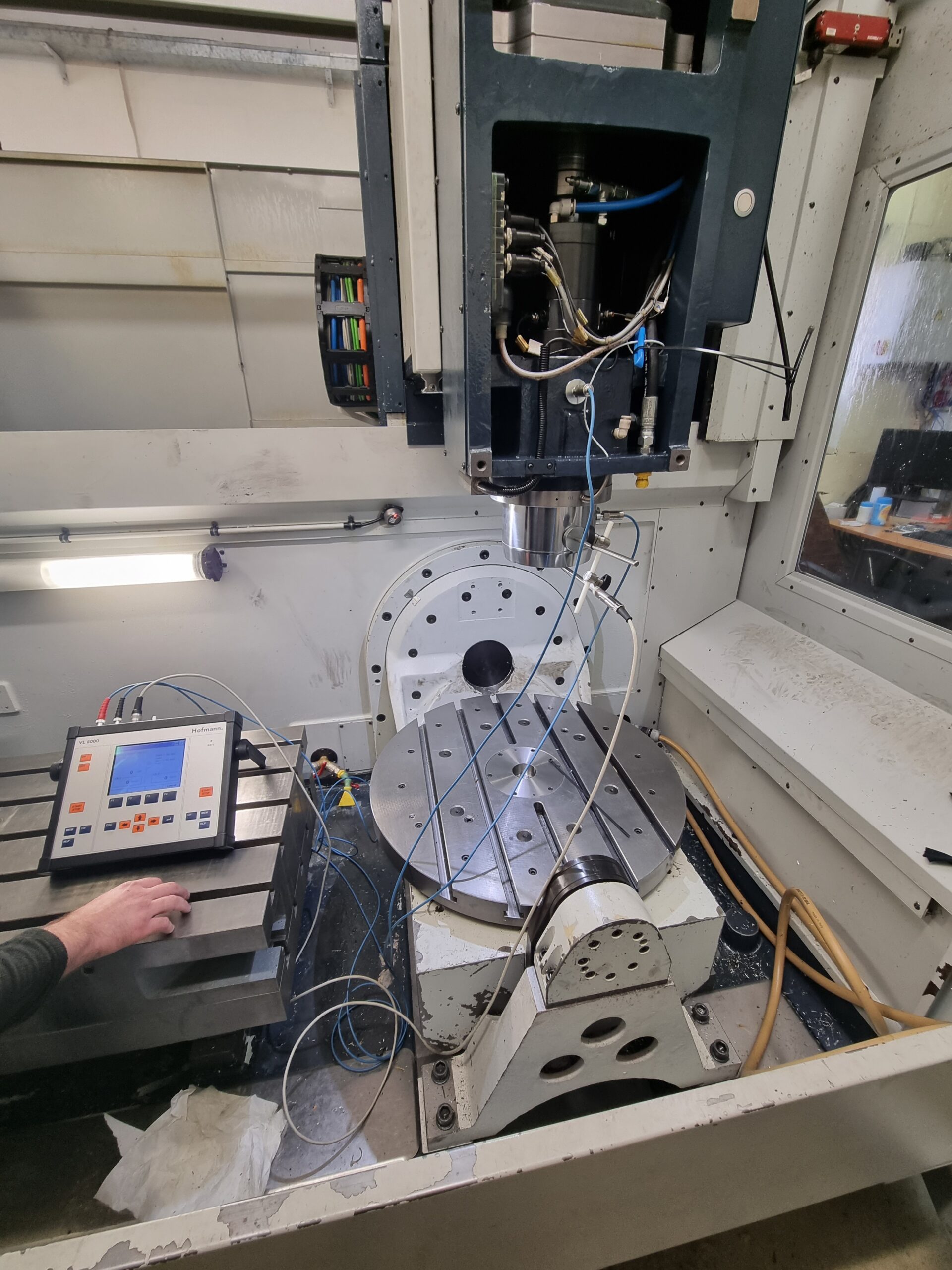

SPINDLE BALANCING MEASUREMENTS AND ADJUSTMENTS WITH HOFMANN VL 8000

We can balance all different rotating devices, both on the machine itself and on our test table, measuring vibrations, clearing measurements.

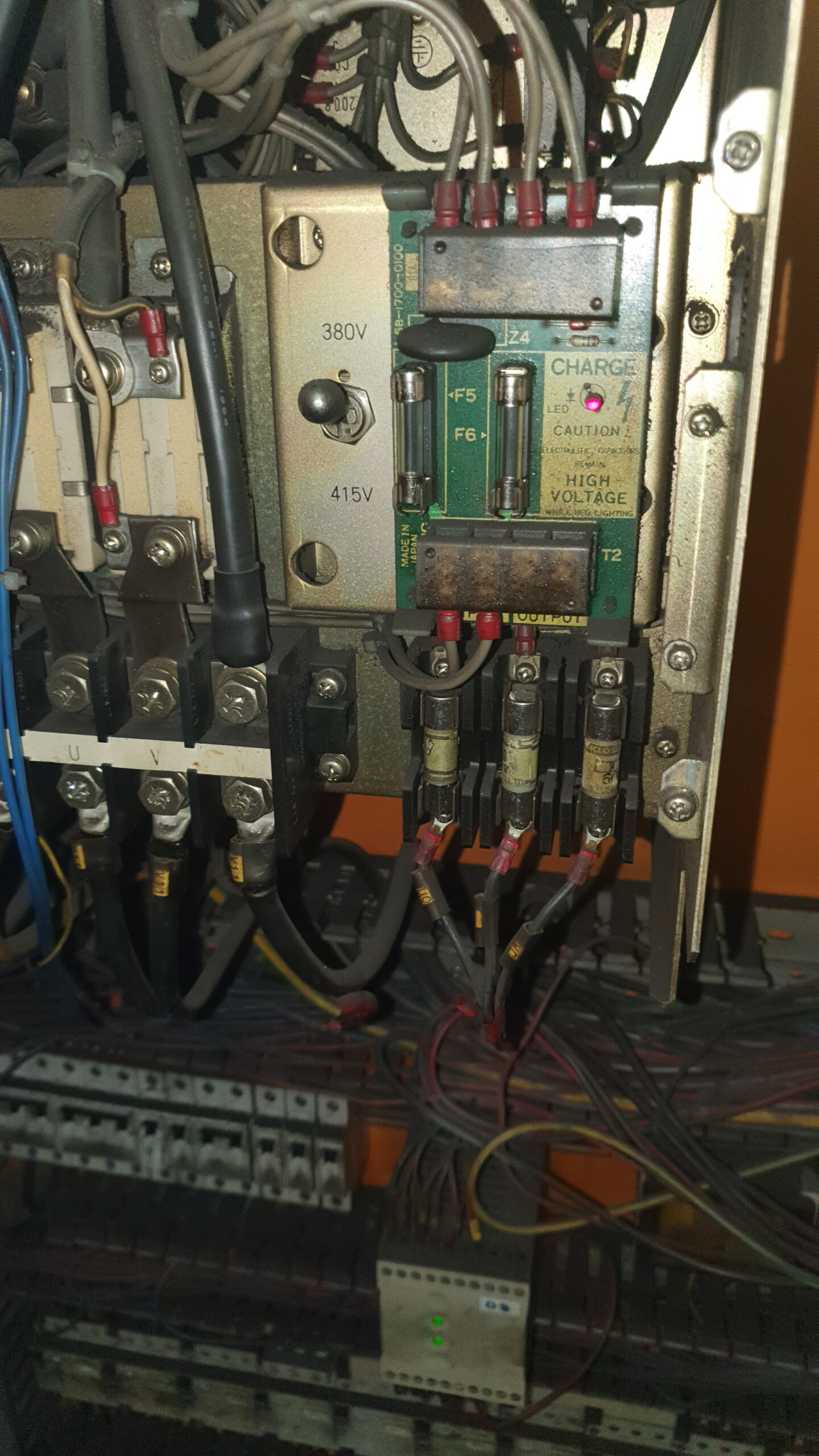

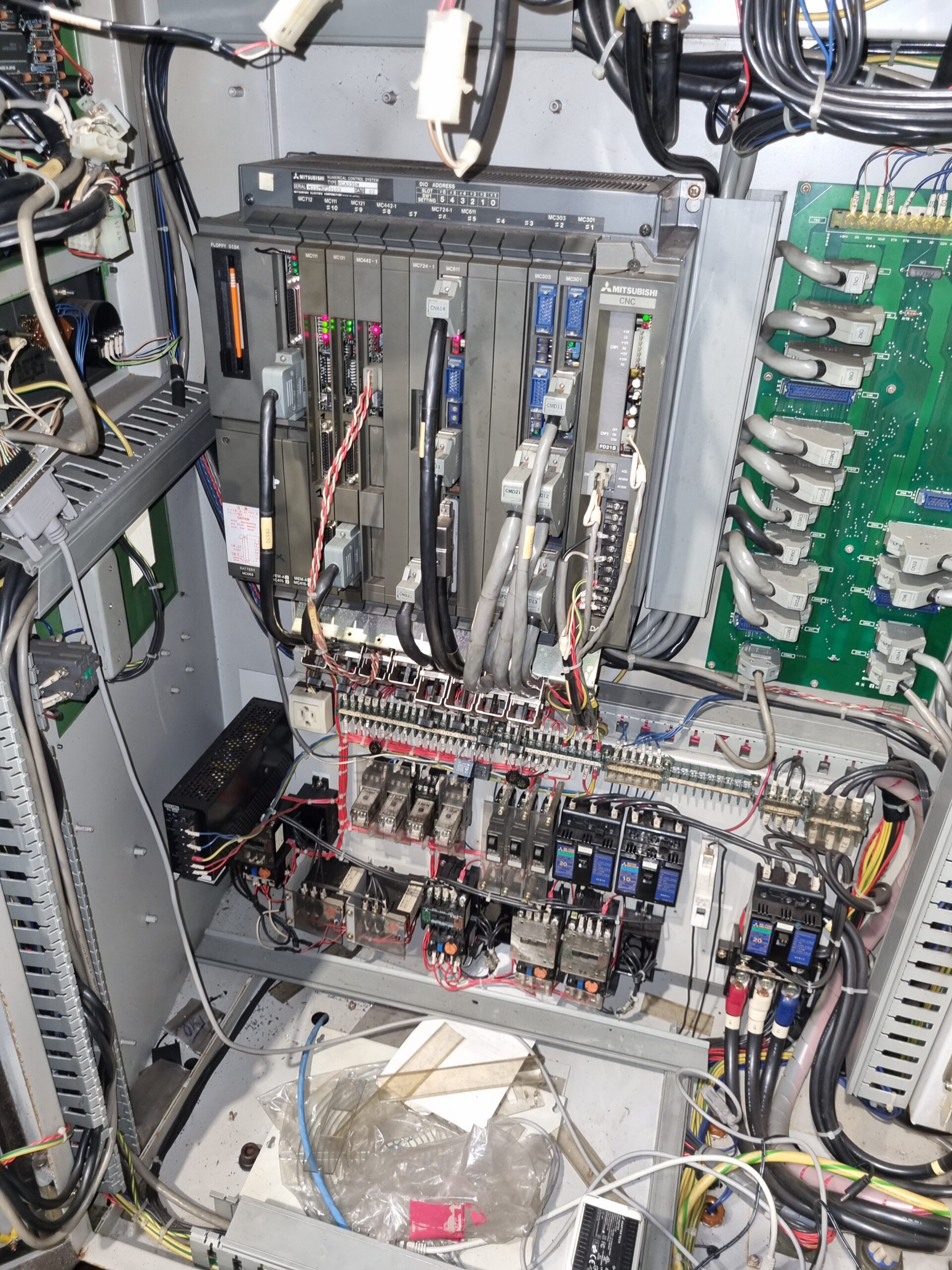

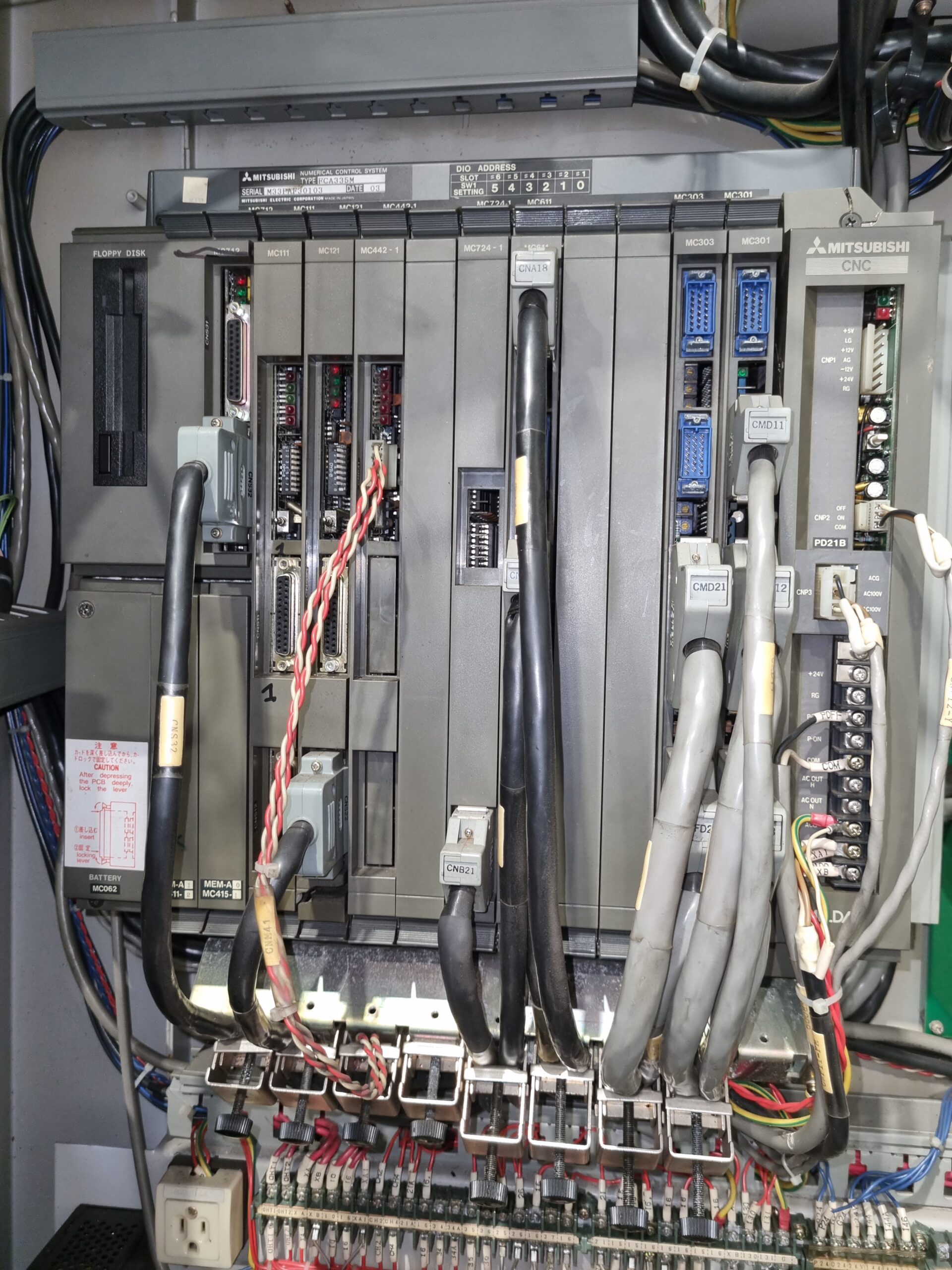

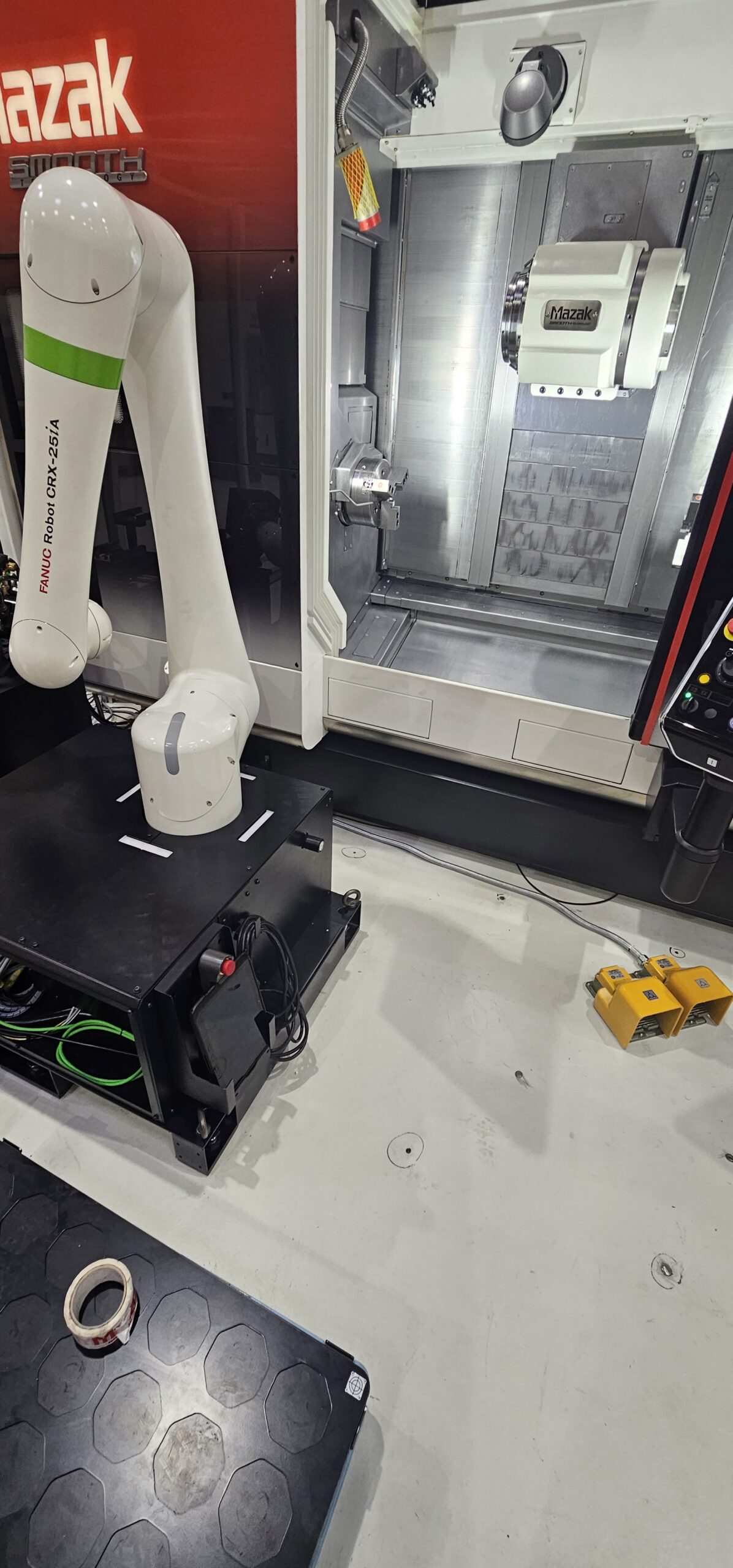

ELELCTRONICS SERVICE ON MACHINES WITH HEIDENHAIN, SIEMENS, FANUC AND MAZATROL CONTROLS

We carry out electronics repairs, motor repairs, controller repairs, card repairs and electronics rebuilds on machines at the customer’s request.

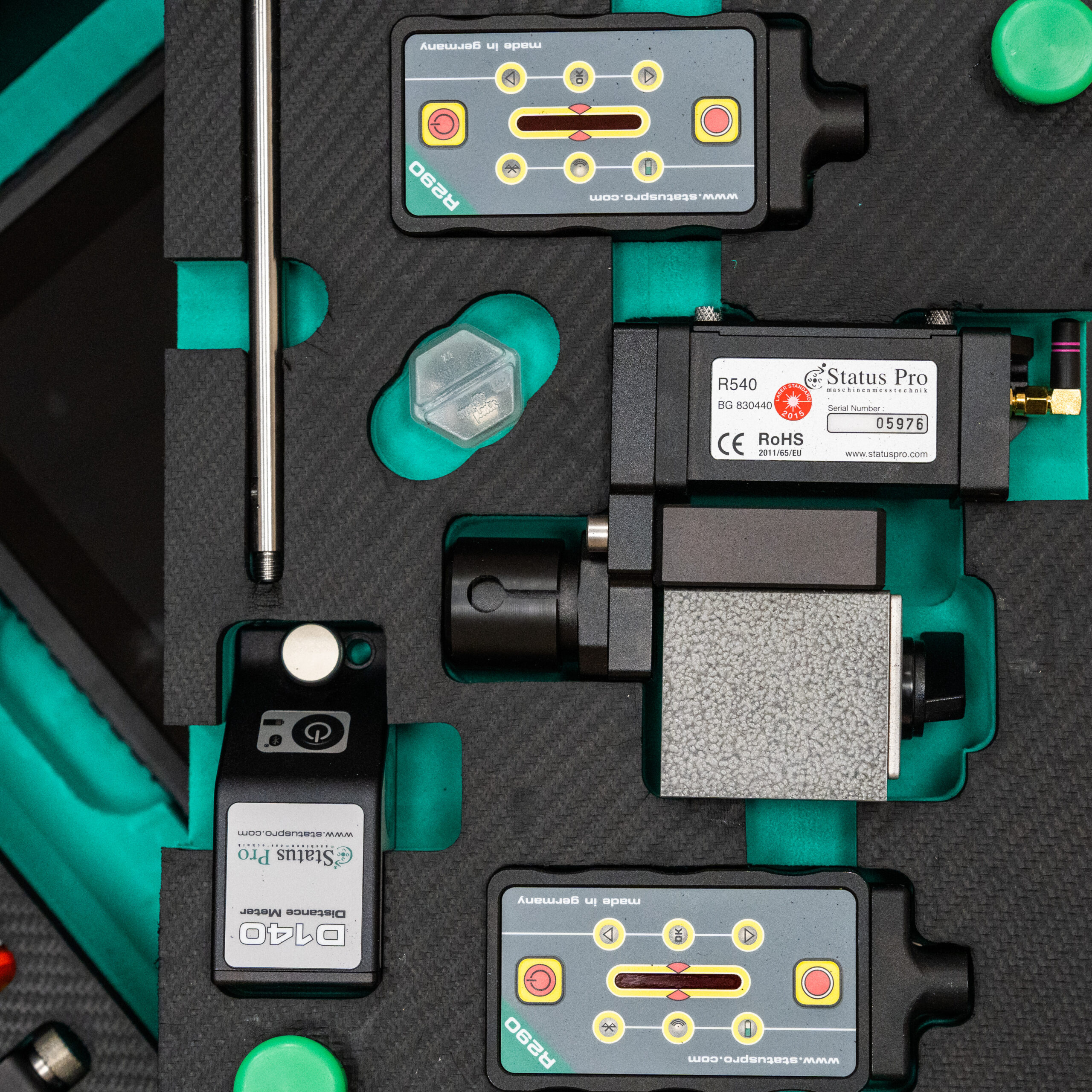

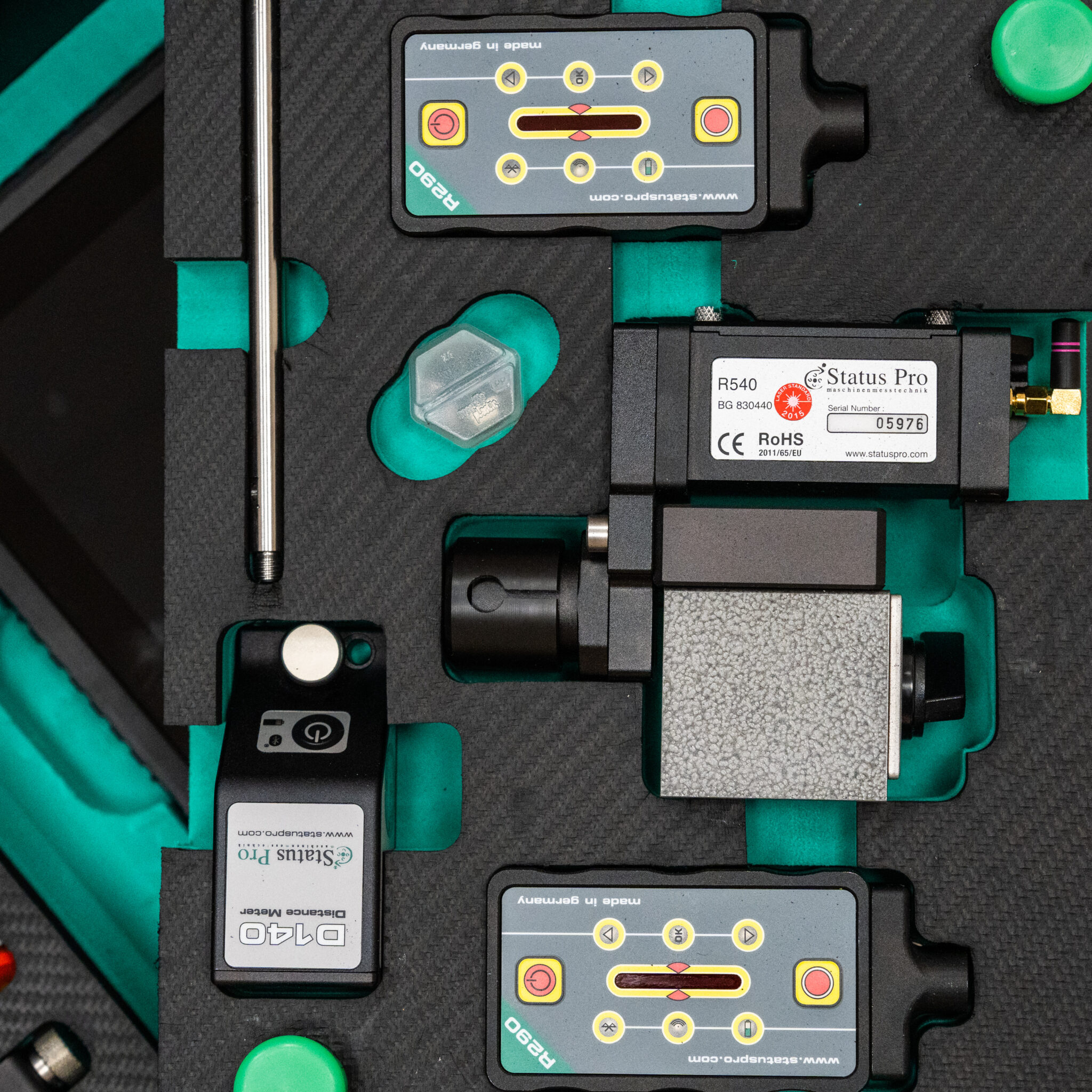

MACHINE CALIBRATION WITH LASER ALIGNMENT STATUS PRO LINE 300

Measurements that can be made are: diameters, perpendicularity, flatness, parallelism and horizontality of guides, axiality of spindles.w

We carry out laser alignment of all types of machines up to 30 000 mm. The system enables you to check the diameters, perpendicularity, flatness, alignment and

horizontality of linear guides, as well as to determine the direction and coaxiality of spindles in rotary machines.

GRINDING OF TAPERS ON SPINDLES

We carry out cone grinding directly on the machine without dismantling the spindle. Grinding of SK and HSK tapers.

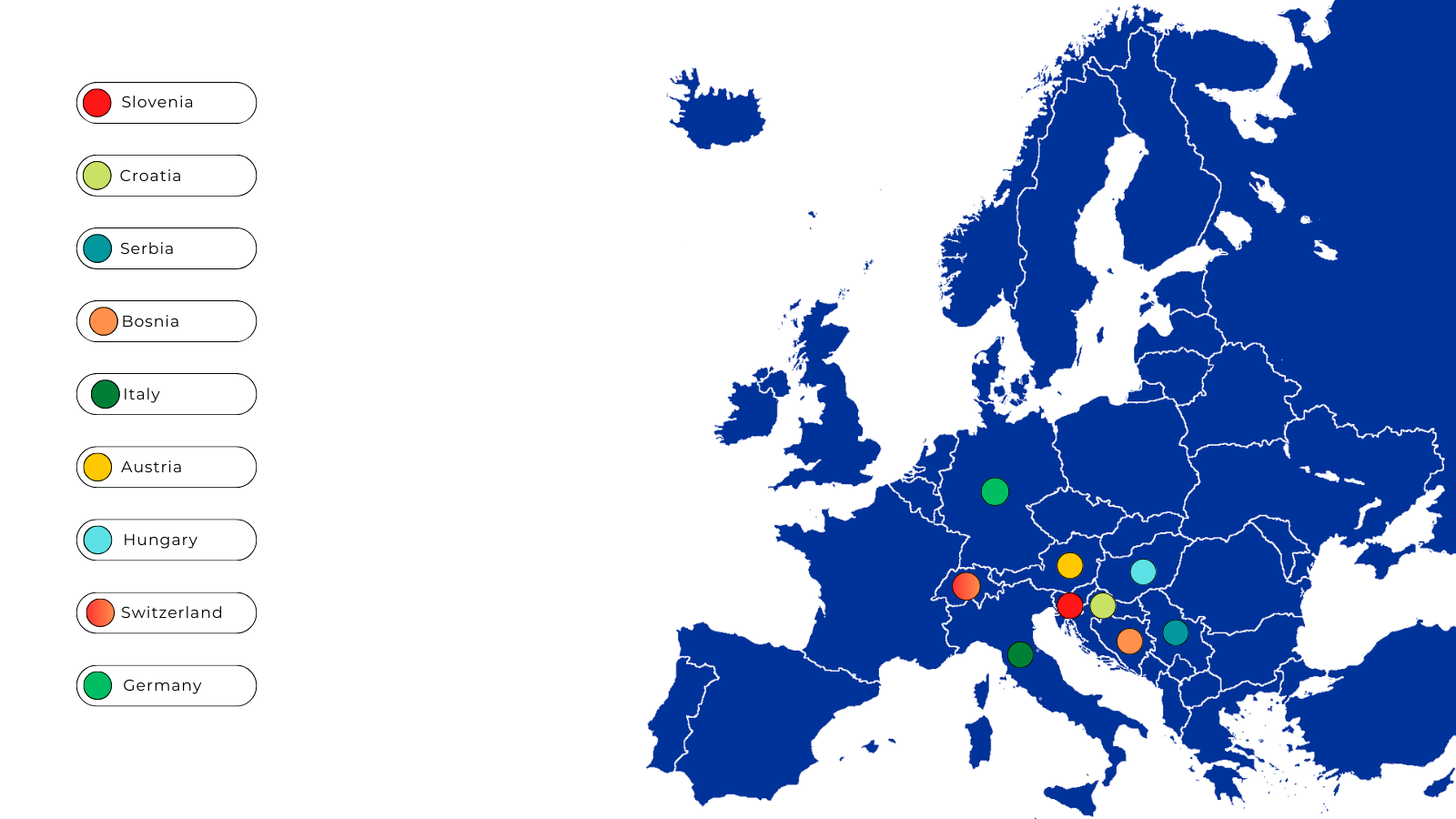

Where are we all present?

Partners

about us

Our young company contains 7 experts with many years of experience in mechanics, geometry and electronics.

STZS CNC Ltd. is your professional and competent partner when it comes to spindle repair, machine servicing, machine geometry, setup and electronics repair. With our service staff in the field of mechanics, electronics and geometry we are a full service partner for all types of your machine tools..

OUR MAINTENANCE PROGRAMME INCLUDES

– Preventive maintenance analysis is required to avoid downtime.

Many maintenance parts are in stock or can be procured at short notice (3 working days).

Maintenance according to needs with no fixed packages, just what is needed.

OUR GEOMETRY OFFER INCLUDES

Analysis of your machine and detection of problems with precision.

– Using the most accurate and market-leading measuring equipment on the market:

ballbar Renishaw, laser geometry STATUS PRO LINE 300, Wyler BLUELEVEL ELECTRONIC.

– Annual maintenance.

— Replacement of worn components.

– Preventive maintenance with component replacement.

MACHINE CONDITION ANALYSIS

– Valuation of machine assemblies.

– Logbook with recommendations for repair.

– Machine geometry with a protocol of results.

CONTACT US

We will be happy to answer your questions and show you how working with the STZS CNC team can benefit you.

Copyright © 2024 stzs-cnc.com